Better Products for Less with Paperboard from Niagara Fiberboard

Niagara Fiberboard manufactures high-strength panels from recycled wood fibers. These single plies are then laminated together into boards of various dimensions, surface textures and colors. The special properties of these materials have led to high acceptance by specifiers and end users.

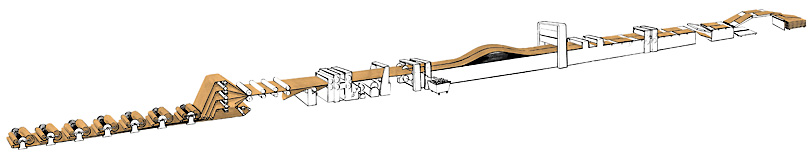

Laminating Process

Based on its background since 1910 as a manufacturer of paperboard produced from recycled wood and paper fiber, Niagara Fiberboard's unique Laminating Machine was designed and built in the mid 1950s.The first of its kind in the United States, this converting laminator has the capacity for more than 500,000 square feet of production per day and is capable of producing panels up to 96" wide, 32' in length and thicknesses to .400". Niagara Fiberboard also offers off-line capabilities of up to 1-1/4" thick.